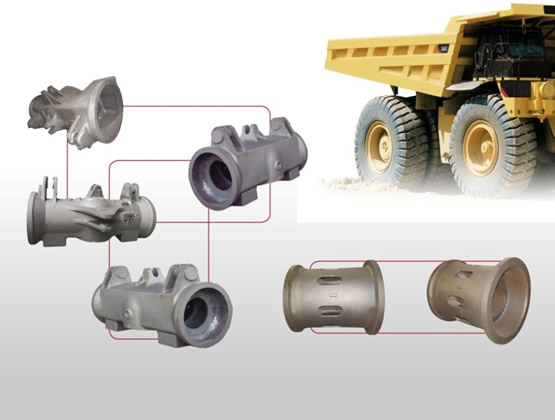

Values and Responsibility > Products and Services wear resistant parts

Mining and mineral processing are high-intensity industries, and

as such, they require extremely durable cast products that can

meet exacting material specifications.Dig, load, truck, crush,

refine, process…and repeat. These operations are at the heart

of the mining and mineral processing industries. And our casting

and forging parts for the drilling and mining industries do the job.

If there is one primary requirement for the steel castings, iron

castings, and nickel-alloy castings that are used to make the

working parts in the mining and mineral processing industry, its

wear-resistance. Our experience in producing the best mining

castings and mineral processing castings means we can produce

not only wear-resistant, but heat-resistant parts as well. This

benefits our customers by extending the working lives of their

products, and ultimately meeting and exceeding the end users’

expectations.

Our abrasion-resistant and wear-resistant irons and steels parts

offer an impressive range of grades, thicknesses and widths, each

with theirown unique characteristics.

Whichever ones you choose, you can be sure they’ll improve the

wear performance of your products and machinery, cut lead times

in your workshop and increase the productivity of your operations.

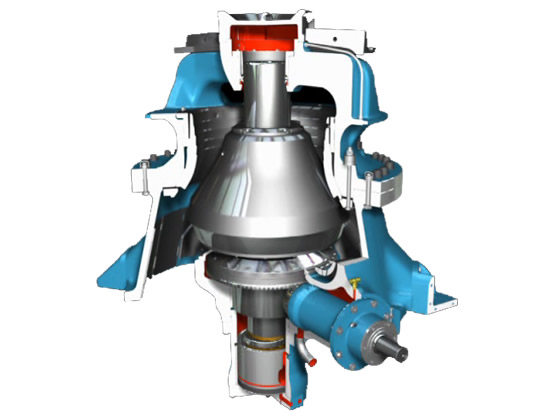

Extreme abrasion resistance has always been the key to our wear

plate’s success. Today, it’s harder and tougher than ever, able to

withstand heavy impact without permanent deformation or

cracking. So if you’re an equipment or machine operator, don’t

worry: our wear-resistant parts can fend off shocks, jolts, bangs,

nicks and jabs. This steel can take a beating and keep on

performing, day after day.

You’ll appreciate that you can easily extend the service life of your

equipment. Not only does this add to the lifespan, but without ugly

cracks and dents your equipment looks better while in use, too.

So whether you need to move a mountain, dig a ditch or carry

a heavy load, our wear-resistant parts works hard to contribute to

a stronger and more sustainable world.

Leaner production begins with reliable performance. Our

wear-resistant parts are made from carefully chosen raw materials

in a tightly controlled, integrated steel mill process.

The result: reliable quality and performance hardness, bendability,

surface quality and flatness – thus high performance for all your

typical wear applications.

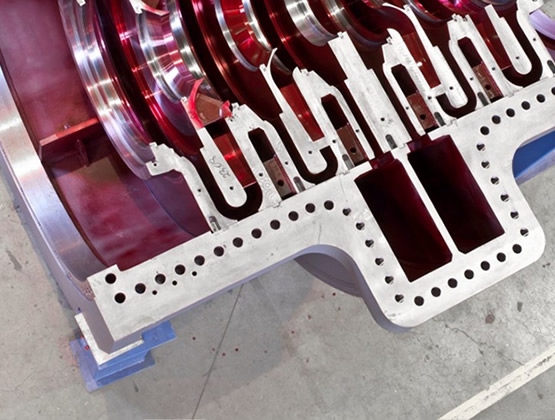

High speed train travel is rapidly becoming the most popular form

of transport for short and medium range distances with Japanese,

European and Chinese manufacturers leading the field. The

braking system of high speed trains is one of the most critical, as

the steel brake discs must take trains from 400 km/h to 0 km/h in

just a few seconds. The G.E.T’s brake discs are the product of

steel processing know-how, analyses and simulations, the latest

cutting-edge technology and strict controls to deliver a product

that meets the most stringent quality standards.

Our experience in producing the best brake discs for high-speed

trains means we can produce not only wear-resistant, but

heat-resistant parts as well. This benefits the brake discs by

extending the working lives, and ultimately meeting and exceeding

the users’ expectations.